5S Tool Organization Made Simple

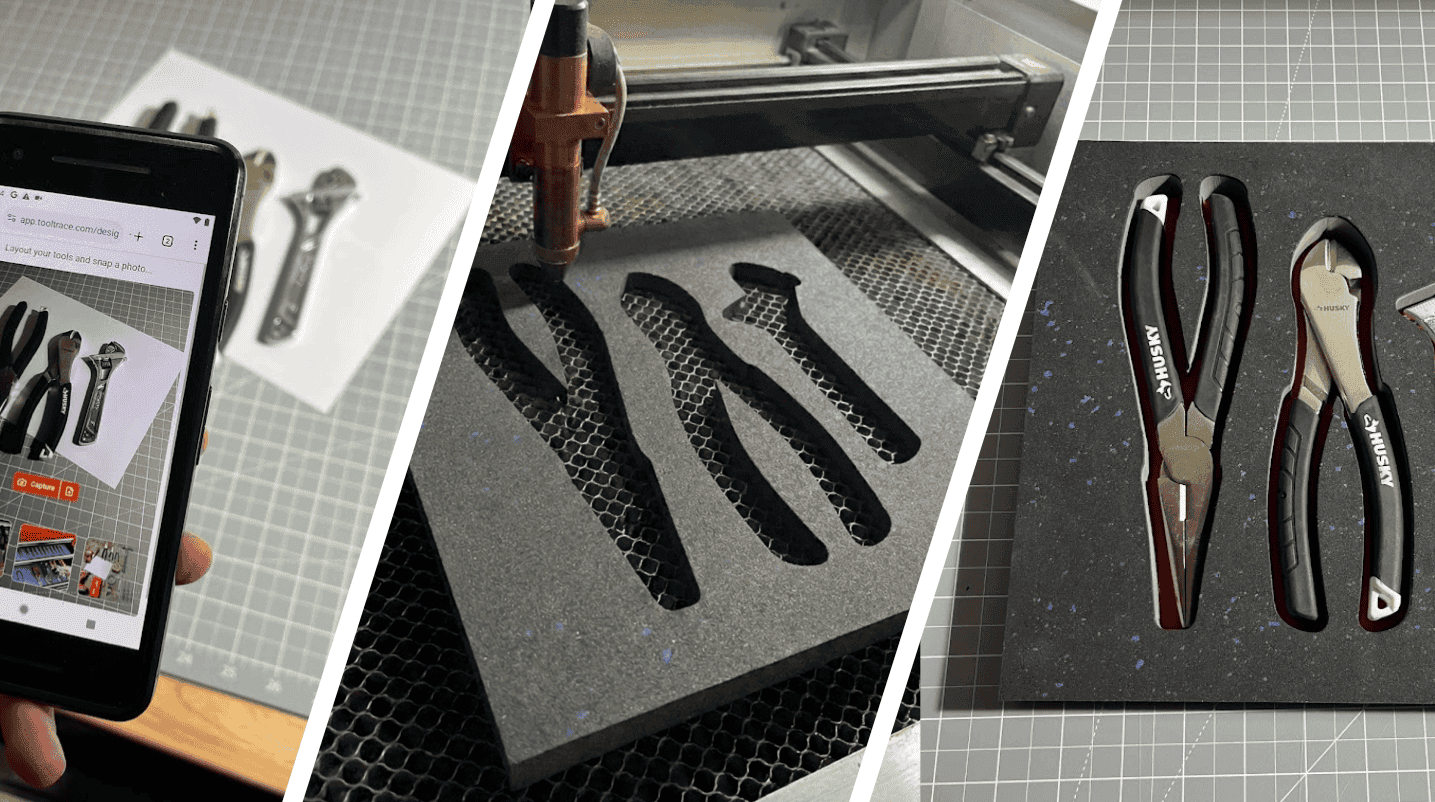

Create custom foam inserts and shadow boards for your manufacturing floor in minutes. Tooltrace uses AI to trace your tools from a photo—no CAD skills required.

What is 5S Methodology?

5S is a systematic approach to workplace organization that originated in Japan as part of the Toyota Production System. The methodology focuses on creating and maintaining an organized, clean, and efficient workspace. Each "S" represents a step in the process.

Sort

Remove unnecessary items from the workspace. Keep only what's needed for current operations.

Set in Order

Organize items so they're easy to find, use, and return. A place for everything and everything in its place.

Shine

Clean the workspace and equipment regularly. A clean workplace is easier to inspect and maintain.

Standardize

Create consistent procedures and visual standards across the organization.

Sustain

Maintain discipline and continuously improve the process over time.

How Tooltrace Supports 5S Implementation

Traditional shadow board creation requires manual measurement, CAD expertise, and expensive outsourcing. Tooltrace eliminates these barriers with AI-powered tool tracing.

Traditional Method

- Hours of manual measurement per drawer

- Requires CAD software expertise

- Expensive outsourcing or custom ordering

- Long lead times for custom foam

With Tooltrace

- Minutes per drawer with photo tracing

- No CAD skills needed—just snap a photo

- Free to use, cut your own foam

- Same-day implementation possible

Visual Management Made Easy

Shadow boards and foam inserts are the foundation of visual tool management. When every tool has a designated spot, you can instantly see:

- Which tools are missing from the workstation

- Where each tool belongs when returning it

- If unauthorized tools have been added to the station

- When a tool needs replacement (empty spot)

Benefits for Manufacturing Operations

Proper tool organization impacts every aspect of manufacturing efficiency. Here's how custom foam inserts and shadow boards created with Tooltrace benefit your operations.

Reduce Tool Search Time

Studies show workers spend up to 30 minutes per shift searching for tools. Designated spots eliminate this waste entirely.

Prevent FOD Incidents

Foreign Object Debris/Damage prevention is critical in aerospace and defense. Visual tool accountability ensures no tools are left behind.

Simplify 5S Audits

Visual tool organization makes audits fast and objective. Auditors can immediately see compliance status at each workstation.

Standardize Across Shifts

Identical layouts across workstations mean any operator can work at any station. Reduces training time and increases flexibility.

Eliminate Tool Hoarding

When tools have homes, there's no need to hide or hoard them. Shared tools are always returned to the correct location.

Reduce Tool Replacement Costs

Missing tools are identified immediately, not months later during inventory. Reduces over-purchasing and lost tool expenses.

Industry Use Cases

Tooltrace serves manufacturing, maintenance, and industrial operations across many sectors. Here are common applications for 5S tool organization.

Manufacturing Floor Tool Cribs

Centralized tool storage with foam inserts ensures tools are checked out and returned properly. Perfect for shared tool rooms that serve multiple production lines.

Maintenance & MRO

Maintenance technicians need the right tools immediately when equipment goes down. Organized tool kits reduce Mean Time To Repair (MTTR) and keep production running.

Aerospace & Defense

FOD (Foreign Object Debris) prevention is mandatory. Shadow boards with exact tool outlines ensure 100% tool accountability after every maintenance operation.

Quality Control & Inspection

Inspection stations require specific gauges and measurement tools. Organized storage ensures the right tools are available and properly calibrated.

Assembly Line Workstations

Each assembly station needs specific tools within arm's reach. Custom foam inserts optimize ergonomics and ensure consistency across all stations.

How It Works

Creating custom foam inserts with Tooltrace takes minutes, not hours. Here's the simple process:

Photograph Your Tools

Trace with AI

Export for Cutting

Supported Output Formats

Frequently Asked Questions

Ready to Implement 5S Tool Organization?

Start creating custom foam inserts and shadow boards today. No CAD skills required—just snap a photo and let our AI do the work.

Need help? Read the full documentation